How to reduce the loss of fine sand by spiral sand washing machine

In industries such as construction, mining, metallurgy, and chemical engineering, sand washing machines are widely used for the cleaning and grading of sand and gravel. However, traditional sand washing machines often waste resources and cause environmental pollution due to the loss of a large amount of fine sand during the sand washing process. In order to solve this problem, in recent years, spiral sand washing machines have innovated in reducing the loss of fine sand and become a popular choice in the industry. This article will explore how the spiral sand washing machine can reduce the loss of fine sand and introduce its innovative methods.

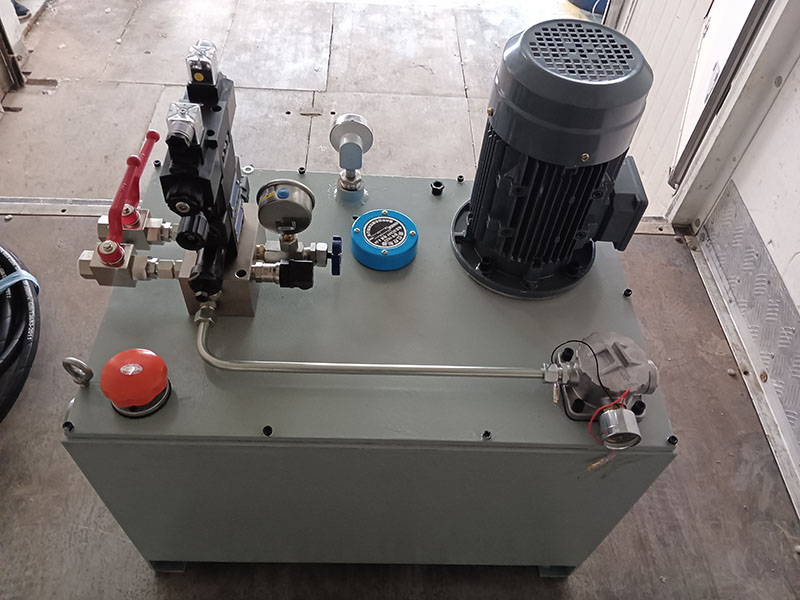

Spiral sand washing machine

1、 Choose the appropriate parameters for the sand washing machine

The parameters of the spiral sand washing machine include sand washing diameter, screw speed, sand washing time, etc. Choosing the appropriate parameters of the sand washing machine can effectively reduce the loss of fine sand. Generally speaking, the smaller the sand washing diameter, the slower the spiral speed, the longer the sand washing time, and the less fine sand loss. However, too small a sand washing diameter and too slow a spiral speed can lead to a decrease in production efficiency, and too long a sand washing time can cause excessive mixing of the sand, affecting its quality. Therefore, it is necessary to choose appropriate parameters for the sand washing machine based on the actual situation.

2、 Improve screening efficiency

In order to reduce the loss of fine sand, the spiral sand washing machine adopts advanced screening devices. Compared to traditional sand washing machines, the screen of spiral sand washing machines is more precise and can effectively separate stone powder and fine sand. At the same time, the spiral sand washing machine also adjusts the inclination and rotation speed of the screen to better layer the stone powder and fine sand, avoid their mixing, and thus reduce the loss of fine sand.

Spiral sand washing machine

3、 Optimize sand washing process

The sand washing process is also very important for reducing the loss of fine sand. Firstly, it is necessary to ensure that the feeding of the sand washing machine is uniform and stable, to avoid feeding too quickly or too slowly, which may cause uneven mixing of the sand. Secondly, it is necessary to control the water volume of the sand washing machine. An appropriate amount of water can play a role in lubrication and flushing, reducing the friction and adhesion of the sand. Finally, it is necessary to clean the filter screen and spiral blades of the sand washing machine in a timely manner to avoid fine sand deposition and blockage, which may affect the sand washing effect.

4、 Optimize the feeding method

The feeding method of the spiral sand washing machine is also one of the key factors to reduce the loss of fine sand. Traditional sand washing machines often directly inject sand and gravel into the machine during feeding, which can easily cause severe collision and friction of sand and gravel, leading to the crushing and loss of fine sand. The spiral sand washing machine adopts interval feeding, which evenly inputs sand and gravel into the machine in batches, effectively reducing the collision and friction of sand and gravel, and reducing the loss of fine sand.

keywords: